Product Center

About Us

Hubei Zhenbang Die Steel Materials Co.,Ltd

Hubei Zhenbang Die Steel Materials Co.,Ltd.(established in 2022) is located in China's advanced manufacturing base and the core hinterland of China's special steel industry - Xisaishan Industrial Park, Huangshi, Hubei. Relying on Huangshi's 3,000-year-old mining and metallurgy cultural accumulation and the industrial cluster advantages of the "cradle of China's steel industry", the company is driven by technological innovation and has rapidly grown into a high-tech enterprise integrating R&D, smelting, forging, heat treatment, fine processing, and testing for die steel full industrial chain. The factory covers an area of more than 6,000 square meters, with an annual output exceeding 20,000 tons. Products are exported to more than 20 countries and regions around the world, and have served more than 2,100 customers.

Founded in

Factory Site

Annual Production Capacity

Customers and Partners

Distribute Across Countries

Core Competencies

Vertically Integrated Production Ecosystem

Fine Machining Accessories

Heat Treatment Technology

Forging Ability

Smelting Process

Production Capacity

Professional Focus

Lab-Grade Quality Control Standards and System

Microscopic control: Using a metallographic microscope (1000x magnification) in conjunction with a low-magnification corrosion test to comprehensively monitor the uniformity of the microstructure.

Performance testing: Brinell/Rockwell hardness tester, ultrasonic flaw detector (3 units)

Component Analysis: German imported direct reading spectrometer (desktop + portable dual configuration)

Original "electric arc furnace + LF refining + electroslag remelting" three-link process, conquering the problem of segregation in large-section die steel

The technical team accounts for over 20%, including 8 senior engineers and several senior experts in the metallurgical industry.

Production Capacity

3000-ton Stamping Presses

Vacuum Degassing Furnace

Gantry Milling Machine

Sawing Machine

Lathe

Annealing Furnace

Electric Arc Furnace

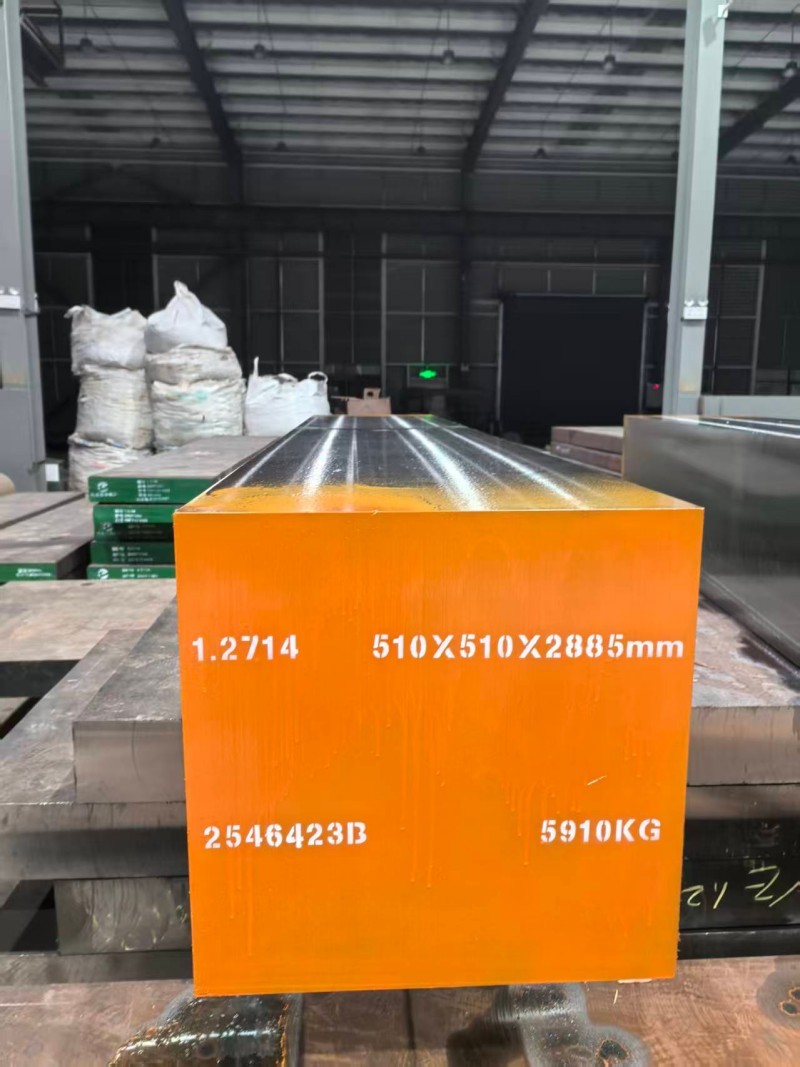

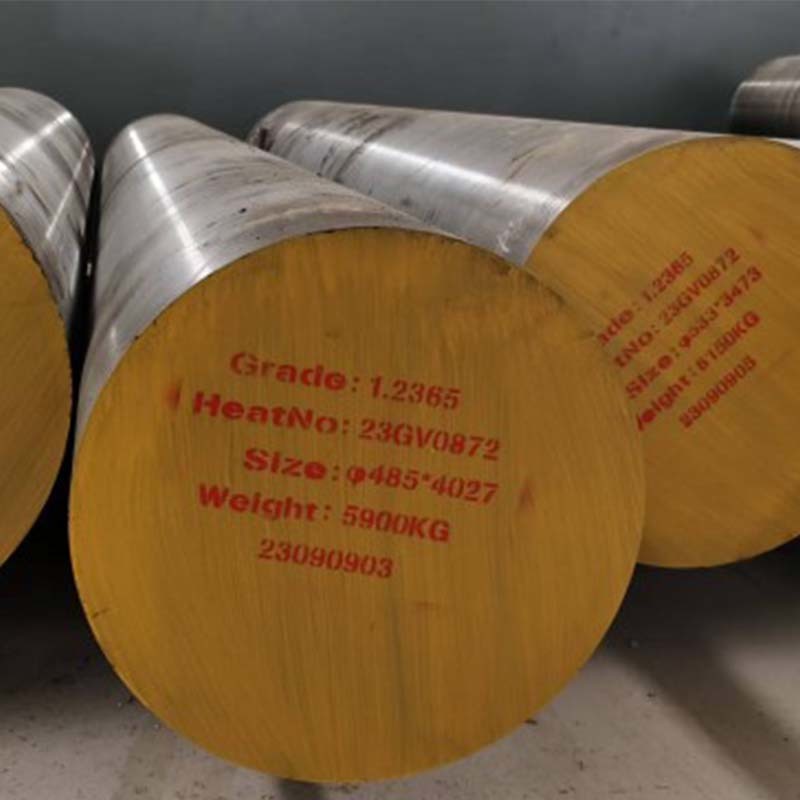

Workshop Inventory

News

Understanding the Latest Advancements in H13 Steel Heat Treatment

H13 steel is widely recognized in the metallurgical industry, particularly for its exceptional toughness, high-temperature strength, and resistance to wear, making it an ideal choice for various applications, including dies, molds, and tooling. The heat treatment process plays a critical role in maximizing these properties, and ongoing advancements in this area continue to enhance the performance

2025-10-26

Unlocking the Potential: Why Classy W1 Tool Steel is a Game Changer in Metalworking

Unlocking the Potential: Why Classy W1 Tool Steel is a Game Changer in Metalworking Table of Contents 1. Introduction to Classy W1 Tool Steel 2. Essential Properties of Classy W1 Tool Steel 3. Applications of Classy W1 Tool Steel in Metalworking 4. Advantages of Using Classy W1 Tool Steel 5. Classy W1 Tool Steel vs. Other Tool Steels 6. The Importance of Heat Treatment 7. Maintenance Tips for Cla

2025-10-25

The Latest Developments in O1 Tool Steel: A Comprehensive Overview

O1 tool steel is a high-carbon, high-chromium tool steel that is known for its exceptional hardness, wear resistance, and ability to maintain sharp cutting edges. As industries continue to evolve, the demand for advanced materials like the newest O1 tool steel is on the rise. This steel grade, classified as an oil-hardening tool steel, is particularly favored for its versatility in various applica

2025-10-24

Discover Affordable Options for P20 Mold Steel When it comes to manufacturing and tooling, **P20 mold steel** stands out as a preferred choice among industries that require durability and reliability. This comprehensive guide will delve into everything you need to know about **P20 mold steel**, including its properties, applications, and how to find affordable options without compromising on quali

2025-10-23

Address: No. 128, Zhang Zhihe Avenue, Dapaishan Village, Xisaishan District, Huangshi City, Hubei Province