About Us

The company covers an area of more than 6,000 square meters and brings together a large number of technical talents in the industry. More than 20% of its employees are professional technicians, including 8 senior engineers. The company has a complete production line for smelting, forging, heat treatment, and fine machining. It has established various processes consisting of arc furnaces, refining furnaces, electroslag furnaces, and non-vacuum induction furnaces; various forging hammers, finishing, spheroidizing annealing, fine machining, and heat treatment equipment combinations for the production of mold materials. A complete quality inspection system has also been established, including raw material inspection, direct-reading spectrum analysis, hardness testing, flaw detection, and high and low magnification and metallographic structure analysis.

Factory Site

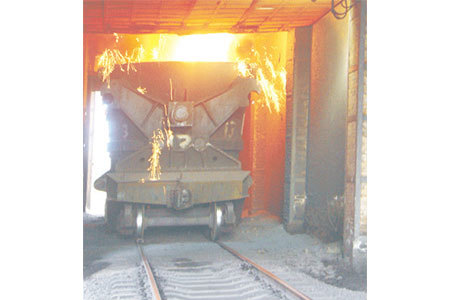

Production Equipment

Product Variants Across Multiple Specs

Customers and Partners

EQUIPMENT DISPLAY

Equipment Display

Address: No. 128, Zhang Zhihe Avenue, Dapaishan Village, Xisaishan District, Huangshi City, Hubei Province