Detailed Introduction

| Steel Grade (GB) |

Comparison of Grades from Various Countries |

Technical Conditions |

Chemical Composition |

||||||||||||||

| C |

Cr |

Mo |

V |

S |

P |

Si |

Mn |

Ni |

W |

Al |

Cu |

Nb |

Co |

B |

|||

| 8407 |

Germany (1.2344) USA (H13) Japan (SKD61)

|

GB/T 1299-2014 |

0.32 ¦ 0.45 |

4.80 ¦ 5.50 |

1.30 ¦ 1.60 |

0.90 ¦ 1.20 |

≤0.030 |

≤0.030 |

0.80 ¦ 1.20 |

0.20 ¦ 0.50 |

|

|

|

|

|

|

|

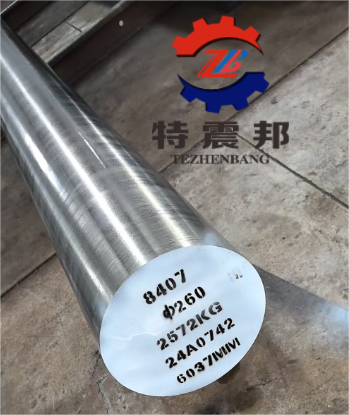

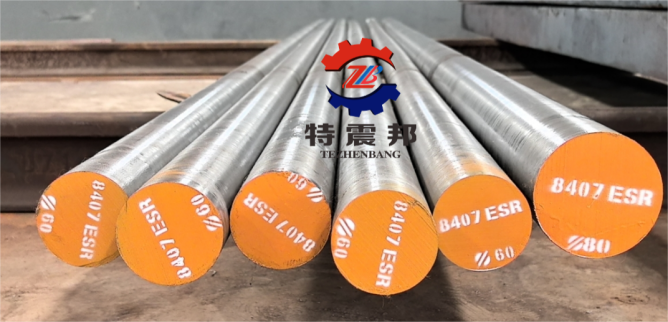

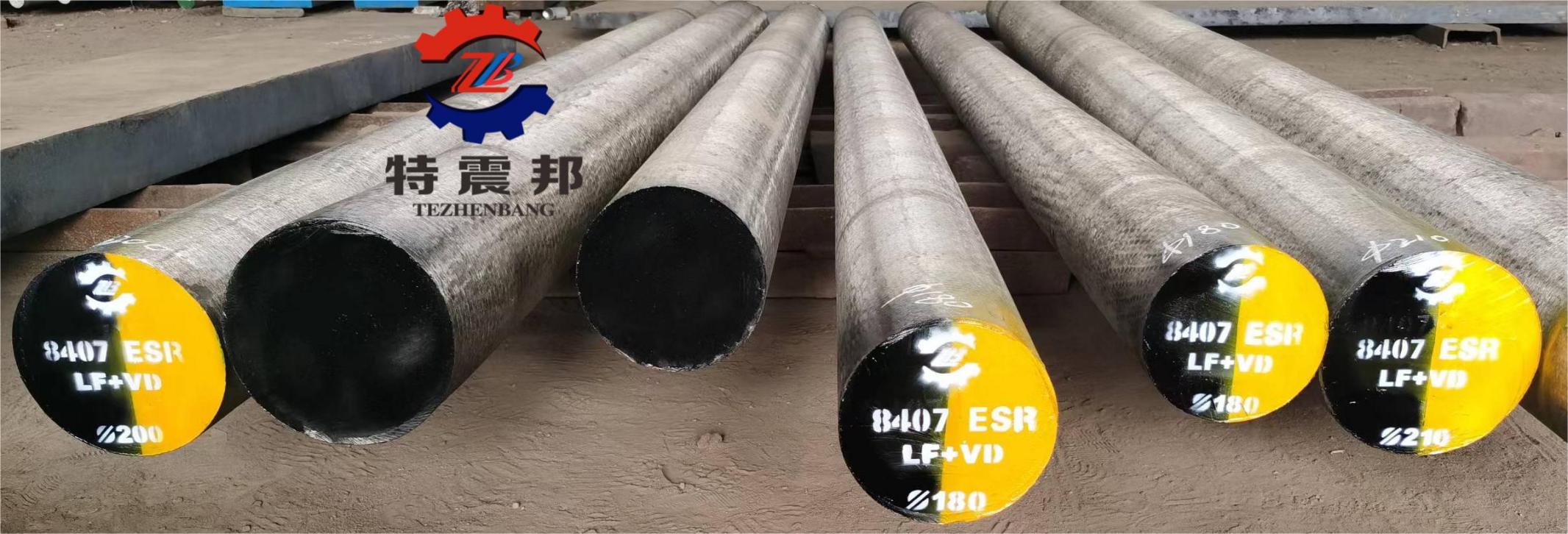

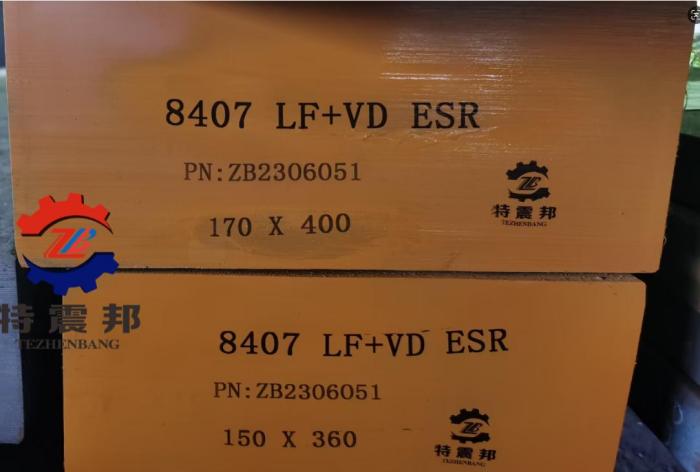

Introduction to 8407 Mold Steel

8407 is a grade from Sweden. Mold steel - Cr, Mo, V alloy tool steel, obtained through special steelmaking processes and strict quality control, resulting in high purity and fine microstructure. The isotropy of 8407 is superior to that of the traditional refining system H13. This is more valuable for molds such as die-casting molds, forging molds, and extrusion molds in terms of resistance to mechanical fatigue and thermal stress fatigue. Therefore, the hardness of 8407 molds can be increased by 1-2 HRC compared to ordinary H13 without sacrificing toughness. High hardness can slow down the occurrence of thermal cracking and improve mold life.

Characteristics of 8407

8407 Mold SteelCorresponding to China: SKD61ESR [1] This is more valuable for the resistance of molds to mechanical fatigue and thermal stress fatigue, such as die-casting molds, forging molds, and extrusion molds. Therefore, the hardness of molds using 8407 can be increased by 1-2 HRC compared to ordinary H13 without sacrificing toughness. High hardness can slow down the occurrence of thermal cracking and improve mold life.

8407Advantages

· Excellent resistance to thermal shock and cracking

· High strength at elevated temperatures

· High toughness and ductility regardless of size, and isotropic

· Excellent machinability and polishability

· Excellent hardenability

· Good dimensional stability during heat treatment

Mechanical Properties

1. Hardness: After quenching and tempering, the hardness of 8407 mold steel can reach 50-55 HRC.

2. Tensile Strength: The tensile strength of 8407 mold steel exceeds 1600 MPa.

3. Compressive Strength: The compressive strength of 8407 mold steel is 2300 MPa.

4. Fracture Toughness: The fracture toughness of 8407 mold steel is above 12 J/cm².

Components

Tin-lead-zinc alloy,Aluminum-magnesium alloyCopper alloy, die-casting mold 46-50 HRC 42-48 HRC insert 46-52 HRC 44-48 HRC core, mold core 46-52 HRC 44-48 HRC gate 48-52 HRC 46-48 HRC nozzle 35-42 HRC 42-48 HRC ejector pin (nitrided) 46-50 HRC 46-50 HRC 46-50 HRC plunger, sleeve 42-46 HRC 42-48 HRC hardening temperature ℃ 1020 - 1050

Applications

8407 mold steel is commonly used for manufacturing high-precision molds and tools such as plastic molds, die-casting molds, extrusion molds, hot-rolled molds, stamping molds, stretching molds, and shearing molds. At the same time, it can also be used to manufacture high-strength mechanical parts and bearings.

In summary, 8407 mold steel has characteristics such as high hardness, high strength, good thermal stability, and excellent machinability, making it suitable for manufacturing high-precision, high-quality molds and tools, widely used in machinery, automotive, electronics, and medical devices.

Spheroidizing Annealing

HeatMold Steelto 850℃ in a protective environment, hold for uniform heating, then cool in the furnace at a rate of 10℃/h to 600℃, and then cool in air.

Stress Relief Tempering

After rough machining, the mold steel must be heated to 650℃, held for 2 hours for uniform heating, then cooled to 550℃ in the furnace, and then cooled in air.

Quenching

|

|

Preheating |

600~800 |

| Temperature ℃ |

Quenching |

980~1080 |

| Commonly Used |

1020 |

|

| Holding Time min |

Quenching Hardness HRC |

|

| 980 |

45 |

50±3 |

| 1050 |

30 |

53±3 |

| 1080 |

15 |

55±3 |

| The calculation method for holding time starts when the center of the steel reaches the quenching temperature. |

|

|

8407 Quenching Medium

Circulating air or gas;

Blowing air or vacuum;

Isothermal cooling at 200~550℃ for 1~100 minutes, then air cooling;

Oil cooling.

Note: ① Steel should be tempered immediately when cooled to 70~100℃.

② To achieve the most appropriate performance of the mold, the quenching cooling rate should be as fast as possible, provided there is no severe deformation or cracking.

8407 Tempering

Tempering at least twice, for more than 2 hours, with a minimum tempering temperature of 180℃, and must cool to room temperature after each tempering. Avoid the tempering brittleness zone between 425~525℃ during tempering.

Suggestions

Control the hardness of the die-casting mold to below 48HRC, and after producing 2000~10000 pieces, perform another tempering or repair welding. After electrical discharge machining, tempering should be done. When designing the mold, try to use larger fillets to avoid stress concentration. Size changes during heat treatment: sample size is 100*100*25mm.

8407 Quenching Changes

|

|

|

Width % |

Length % |

Thickness % |

| 1000℃ Oil Quenching |

Minimum |

-0.08 |

-0.06 |

0.00 |

| Maximum |

-0.02 |

-0.05 |

+0.05 |

|

| 1020℃ Air Cooling |

Minimum |

-0.15 |

-0.16 |

+0.30 |

| Maximum |

+0.03 |

+0.02 |

+0.05 |

|

8407 Nitriding

To improve the wear resistance of the mold surface, nitriding treatment can be performed to generate a hard nitrided layer on the mold surface. Nitriding at 525℃ can achieve a surface hardness of 1000~1250HV.

| Nitriding Temperature ℃ |

Nitriding Time h |

Hardening Layer Depth mm |

| 525 |

20 |

0.20 |

| 525 |

30 |

0.25 |

| 525 |

60 |

0.30 |

At 575℃, soft nitriding for 2 hours can achieve a surface hardness of 950~1000HV, with a hardening layer depth of 0.01~0.02mm.

8407 Grinding

Correct grinding techniques can prevent the formation of cracks and increase the tool's lifespan. If the material is ground in a low-temperature tempered state, it is highly sensitive to cracking. Only edge-trimmed, soft, and open-grain type grinding wheels can be used, with appropriate grinding speed and good coolant.

8407 Electrical Discharge Machining

If the material is electrically discharged in the quenched-tempered state, the tool must undergo further tempering at a temperature below 25℃ of the original tempering.

key word:

Hot working mold steel

Cold working mold steel

Plastic mold steel

Forging series

Message Consultation

Service hotline:

Company address

Telephone

Address: No.128 Zhangzhihe Avenue, Dapaishan Village, Xisaishan District, Huangshi City, Hubei Province