Detailed Introduction

| Steel Grade (GB) |

Comparison of Grades from Various Countries |

Technical Conditions |

Chemical Composition |

||||||||||||||

|

|

|

|

C |

Cr |

Mo |

V |

S |

P |

Si |

Mn |

Ni |

W |

Al |

Cu |

Nb |

Co |

B |

| Cr12Mo1V |

Germany (1.2601/x165CrMoV12) Japan (SKD11) USA (D2) Sweden (1.2310) South Korea (STD11) Russia (x12M) Italy (x165CrMoW12KU) |

GB/T 1299-2014 |

1.40 ¦ 1.60 |

11.00 ¦ 13.00 |

0.80 ¦ 1.20 |

0.20 ¦ 0.50 |

≤0.030 |

≤0.030 |

≤0.40 |

≤0.60 |

≤0.25 |

|

|

≤0.25 |

|

|

|

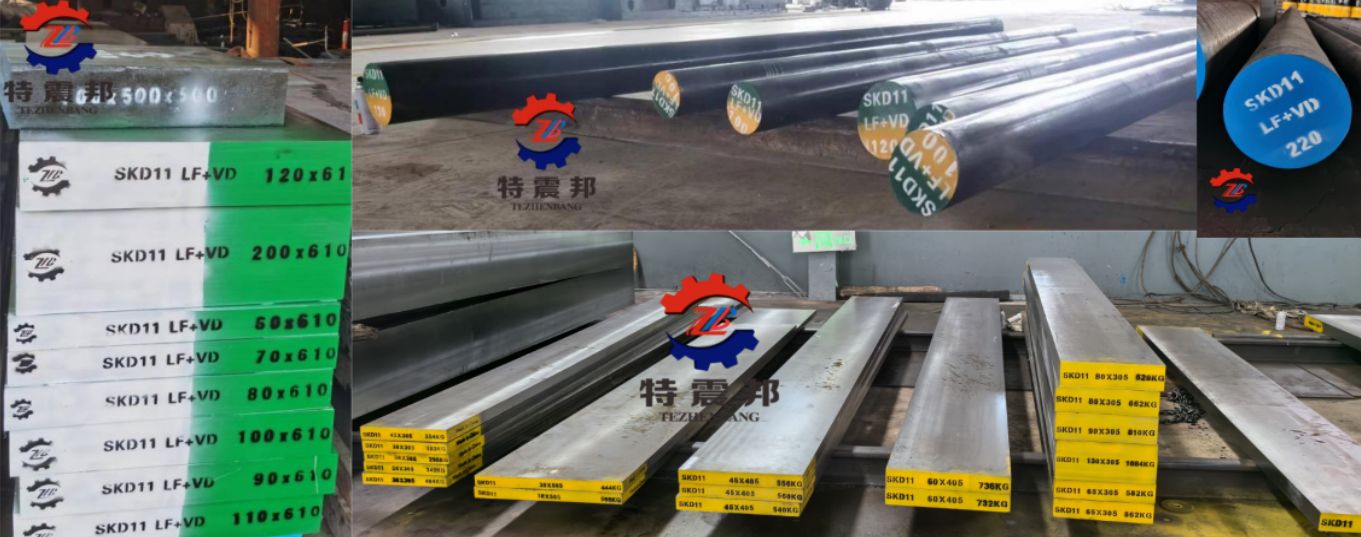

Scope of Application

SKD11 is a high wear-resistant toughness general-purpose cold work mold steel, high carbon high chromium alloy tool steel, and vacuum degassed refined steel. The steel is pure, has good hardenability with good hardenability, and has low quenching deformation. This steel can be processed well after spheroidizing annealing, with fine and uniform carbide particles, and there is no need to worry about quenching cracks due to the special addition of strengthening elements molybdenum and vanadium.

Cold work mold steel has higher hardenability, quenching and tempering hardness, wear resistance, and strength. It is used to manufacture various cold stamping molds and tools with larger cross-sections, complex shapes, and heavy working conditions, such as punching dies, cutting dies, rolling dies, deep drawing dies for steel plates, circular saws, standard tools and gauges, thread rolling dies, etc.

Produced by electric furnace vacuum refining, forged blank, uniform eutectic carbide, high hardenability, high wear resistance, high toughness, and small volume deformation during quenching; therefore, its market usage is very large.

Characteristics

1. Good high-temperature strength and toughness, better wear resistance, easy to cut;

2. SKD11 is a cold mold steel with high strength, toughness, and heat resistance balance. In recent years, with the development of isotropic products, it has increasingly developed towards high toughness and other aspects, which can make the mold life longer, performance more stable, and easy to process with small thermal deformation.

SKD-11 Product Features

SKD11 Mold Steel

(1) It has undergone vacuum degassing refining, so the internal quality is extremely clean.

(2) Good machinability.

(3) Good hardenability, can harden with air cooling, no need to worry about quenching cracks.

(4) Very small thermal deformation during heat treatment, very small quenching deviation, most suitable for molds with precision requirements.

(5) Excellent wear resistance, most suitable for use as cutting dies for stainless steel or high-hard materials.

(6) Good toughness.

SKD-11 Deep Cryogenic Treatment

To achieve the highest hardness and dimensional stability, the mold is deep-frozen immediately after quenching at -70 to -80 degrees Celsius for 3-4 hours, and then tempered. The hardness of tools or molds after deep cryogenic treatment is 1-3 HRC higher than that of conventional heat treatment. For parts with complex shapes and large dimensional changes, there is a risk of cracking during deep cryogenic treatment.

SKD-11 Nitriding Treatment

After nitriding treatment of molds or workpieces, a layer of hardened structure with high hardness and certain corrosion resistance is formed on the surface.

Nitriding treatment at 525℃

The surface hardness of the workpiece is about 1250HV, and the nitriding time affects the diffusion layer as shown in the table below. Nitriding Time (hours) 20 30 60 Diffusion Layer Depth mm 0.25 0.30 0.35

Soft Nitriding Treatment at 570℃

The surface hardness of the workpiece is about 950HV. Usually, soft nitriding treatment for 2 hours can achieve a hardening layer depth of 10-20um. Grinding processing of the blank or working in a low-temperature tempering state can easily lead to grinding cracks. To prevent cracks, small grinding feed amounts should be used for multiple grindings, along with good water cooling conditions.

Wire cutting processing of complex shapes or larger molds often encounters cracking phenomena.

To prevent cracking, it is recommended to use gas quenching and high-temperature tempering treatment to reduce heat treatment stress, or to perform cavity pre-processing on the mold blank.

SKD-11 Heat Treatment

Quenching: First preheat to 700-750℃, then heat to 1000-1050℃ and cool in still air. If the thickness of the steel tool is more than 6 inches, heating to 980-1030℃ and quenching in oil is better.

Tempering: Heat to 150-200℃, hold at this temperature, and then cool in still air.

Hardness: HRC above 61.

Annealing: Heat to 800-850℃, hold at this temperature for 1-3 hours, and allow to cool gradually in the furnace.

Forging: 1050-950℃.

Quenching and tempering specifications

Quenching temperature 1010°C, air cooling. Tempering temperature 200℃, hardness 58~60HRC.

SKD-11 Applications

SKD11 is most widely used in aluminum and zinc die-casting mold materials. This steel contains tungsten and is a high-temperature resistant alloy steel, suitable for hot work, aluminum, magnesium, zinc, copper alloy die-casting molds, groove cutting tools, scissors, and hot forging actions, plastic molds, hot working hinge tools, rolling knives, general hot working forging molds, hot bolt molds, and various tools for hot working.

SKD-11 Usage Methods

Used in the "quenching + tempering" state

Used in the "quenching + cold treatment + tempering" state (suitable for high precision and size stability requirements)

Used in the "quenching + tempering + nitriding treatment" state (suitable for surface high hardness requirements)

When cutting, the saw blade speed should not be too fast, 25m/min is appropriate, and the cutting efficiency should be maintained at around 9cm2/min to 20cm2/min.

Typical Applications of SKD-11

Used for making plastic molds, scissors, circular saw blades, hardware stamping molds, and forming rollers.

Used to make cold work or hot work finishing molds, roller edges, thread molds, line molds, transformer core punching molds, cutting steel plate rolling knives, steel pipe forming rollers, special forming tubes, nail head molds, etc.

High-efficiency blanking molds, punching molds, and embossing molds for steel plates with a thickness of ≤6mm.

Various scissors, embedded parts, and wire drawing molds.

Cold heading molds for slip blocks, deep drawing forming molds, and cold extrusion molds.

Thermosetting resin molds, general plastic molds.

key word:

Hot working mold steel

Cold working mold steel

Plastic mold steel

Forging series

Message Consultation

Service hotline:

Company address

Telephone

Address: No.128 Zhangzhihe Avenue, Dapaishan Village, Xisaishan District, Huangshi City, Hubei Province