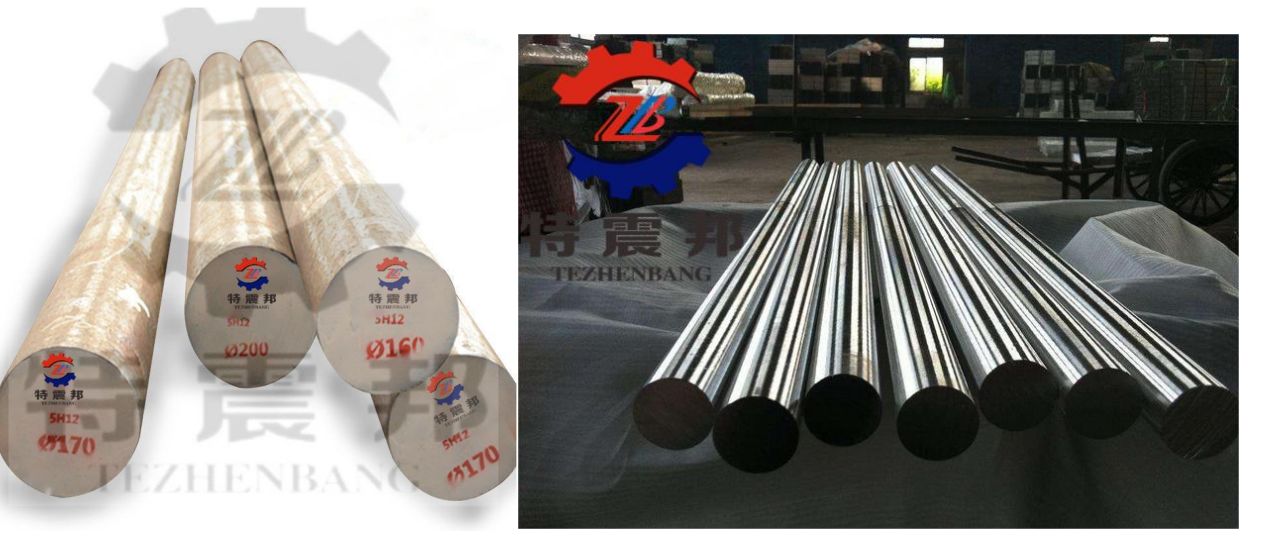

5H12 High-Carbon Tool Steel

Classification:

5H12 High-Carbon Tool Steel is commonly used to manufacture hot extrusion dies, forging hammers, forging dies, precision forging machine die inserts, die-casting dies, etc., for aluminum, copper, and their alloys. At the same time, 5H12 is also a high-carbon steel specially used for the production of blades and rollers, with a carbon content of about 0.6%.

Tel:

Detailed Introduction

High-Carbon Tool Steel is a tool steel with a high carbon content, usually between 0.6% and 1.4%. Due to its high carbon content, it has excellent hardness and wear resistance, and is suitable for manufacturing various cutting tools, molds, and precision parts working under high loads and high temperatures. After proper heat treatment, it can reach a higher hardness and show excellent cutting performance and wear resistance.

Its main characteristics are high hardness, high strength, good wear resistance, and deformation resistance. It can maintain a high hardness in a high temperature environment, so it is often used to make cutting tools, gauges, molds and other products that require wear resistance and high temperature resistance. By adjusting its heat treatment process, the performance of the steel can be further improved to meet different application requirements.

|

Steel Grade (GB) |

Comparison of Grades from Various Countries |

Technical Conditions |

Chemical Composition |

||||||||||||||

|

C |

Cr |

Mo |

V |

S |

P |

Si |

Mn |

Ni |

W |

Al |

Cu |

Nb |

Co |

B |

|||

|

5Cr5MoWVSi |

USA (5H12) |

Agreement |

0.45 ¦ 0.55 |

4.75 ¦ 5.50 |

1.00 ¦ 1.75 |

0.40 ¦ 0.60 |

≤0.030 |

≤0.030 |

0.80 ¦ 1.20 |

0.20 ¦ 1.50 |

|

1.00 ¦ 1.50 |

|

|

|

|

|

Basic Information

5H12 High-Carbon Tool Steel is commonly used to manufacture hot extrusion dies, forging hammers, forging dies, precision forging machine die inserts, die-casting dies, etc., for aluminum, copper, and their alloys. At the same time, 5H12 is also a high-carbon steel specially used for the production of blades and rollers, with a carbon content of about 0.6%. Within a certain range, the higher the carbon content of the steel, the higher the hardness after heat treatment, and the finer the grind of the blade, the more the tool very sharp. Compared with ordinary knives, the manufacturing process of blade steel is more refined, the blade is not easy to wear, and the blade surface is not easily corroded by acidic substances, which is an advantage that ordinary knives cannot achieve. Blade steel has extremely high hardness, corrosion resistance, wear resistance, and is not easily rusted. The blade always remains sharp, which is especially important for cutting thin slices, and it is also easier to clean. The shield machine blades commonly found on the market are usually made of 5H12 or high-carbon H13 steel.

Heat Treatment Process of 5H12 Mold Steel:

Forming Temperature (C) / 900℃~1100℃ Annealing Temperature (C) / 800℃~840℃; Stress Relief Temperature (C) / 600℃~650℃ Annealing Hardness (HB) / 250max; Quenching Temperature (C) / 1000℃~1050℃ Quenching Medium / Isothermal Bath; Tempering Temperature (C) / 500℃~530℃ Tempering Hardness (HRC) / 58~60;

Quenching Temperature 1020-1050℃ Fire Medium Oil, Air, Quenching Hardness HRC57-60 Tempering: Tempering Temperature 600℃, Tempering Twice, Tempering Hardness HRC47-49

Annealing: 860-890℃ Hardness: ≤229HB

If gas nitriding or carburizing is performed, it can further strengthen the mold, but the nitriding temperature should not exceed the tempering temperature to ensure that the core strength is not reduced, thereby increasing the service life of the mold.

Usually, two tempering processes are adopted, with the second tempering temperature being 20℃ lower than the first.

5H12 has good heat resistance, with good strength and hardness at higher temperatures, high wear resistance and toughness, and good thermal fatigue performance. Excellent comprehensive mechanical properties and high tempering stability.

key word:

Hot working mold steel

Cold working mold steel

Plastic mold steel

Forging series

Message Consultation

Service hotline:

Company address

Telephone

Address: No.128 Zhangzhihe Avenue, Dapaishan Village, Xisaishan District, Huangshi City, Hubei Province