Detailed Introduction

| Steel Grade (GB) |

Comparison of Grades from Various Countries |

Technical Conditions |

Chemical Composition |

||||||||||||||

|

|

|

|

C |

Cr |

Mo |

V |

S |

P |

Si |

Mn |

Ni |

W |

Al |

Cu |

Nb |

Co |

B |

| 4Cr13MoV |

USA (420ESR) Sweden (S-136) Germany (1.2083) Japan (SKS538) Austria (M310) |

GB/T 1220-1992 |

0.36 ¦ 0.45 |

12.00 ¦ 14.00 |

|

|

≤0.030 |

≤0.030 |

≤0.60 |

≤0.80 |

≤0.60 |

|

|

|

|

|

|

Out-of-furnace refining (LF) + vacuum degassing (VD) + electroslag remelting refining (ESR), resulting in a purer and finer structure, excellent corrosion resistance, polishability, good wear resistance, machinability, and excellent dimensional stability during quenching.

S136 is commonly referred to as 4Cr13 in China, but based on customer requirements, it can be specifically divided into three types: 4Cr13, 4Cr13MoV, and 4Cr13NiMoV. Therefore, it is best for customers to provide the required composition when ordering this material, as the Ni, Mo, and V can be adjusted according to specific customer needs.

Characteristics

1. Excellent corrosion resistance

2. Excellent polishability

3. Excellent wear resistance

4. Excellent machinability

5. Excellent stability during quenching

Introduction

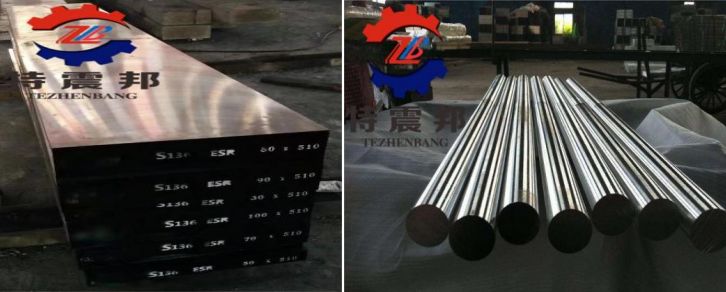

S136

Factory Hardness:

Soft annealing to HB 250 maximum

Applications:

● Corrosion and rust resistance for injection molding materials that are corrosive, such as PVC, acetate, or molds that must work and be stored in humid environments.

● Wear resistance for injection molding materials with high abrasion (including thermosetting injection molds) or molds that require a long working time, such as electronic parts, disposable cutlery, utensils, etc.

● High smoothness surface for producing optical products, such as cameras, sunglasses, chemical instruments, and plastic products.

key word:

Hot working mold steel

Cold working mold steel

Plastic mold steel

Forging series

Message Consultation

Service hotline:

Company address

Telephone

Address: No.128 Zhangzhihe Avenue, Dapaishan Village, Xisaishan District, Huangshi City, Hubei Province